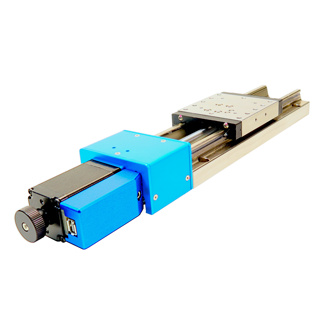

Motorized Stage X-Axis CXN6075-P1

Description

GMT's CXN6075-P1 Motorized Linear Stages are suitable for a variety of applications in laser microprocessing, metrology, and optical alignment and assembly systems. The monoblock design creates a decisive advantage in terms of cost optimization and thermal stability. With this concept, no separate guide elements are required, as these are incorporated into the profile and the body and guide therefore consist of one piece.

The precision motorized stages of our CXN series have a preloaded ball screw and a positioning carriage guided by a recirculating ball bearing system, which allows long and precise traverse paths. In combination with the optionally available closed-loop stepper motor, repeat accuracies of less than 1 µm and a maximum speed of up to 60 mm/s can be achieved.

The new Ethernet connector Harting ix Industrial® is used for the motorized linear stages. The robust and miniaturized Ethernet interface replaces the RJ45 connection and ensures that your plug connection is held securely.

Thanks to the design, the sliding tables can be combined to form a multiple axis system. The drilling pattern also allows the assembly of our goniometer, rotation or lifting tables.

The advantages of the GMT high precision motorized stage systems:

- Cost-optimized concept

- Repeatability < 1µm

- Ball screw for high cycles and speeds

- Made of stainless steel

- High thermal stability

- 2-phase stepper motor from Nanotec

- Optional closed-loop stepper motors, optionally with integrated or external controller

- Harting ix connector® – for a secure connection

- Optical limit switches

- Easy to use - Plug & Play

- Compatible with other manufacturers

- For use in research, laser and measurement technology, in laboratories and in the industrial sector for the automation of precise and complex processes

The combination of our compact linear stages with the Fastech Ezi-SERVO stepper motors increases repeatability and guarantees smooth and precise positioning. Due to the integrated rotary encoder, with a resolution of >16000 pulses per revolution (ppr), the system runs permanently in closed loop mode. In this way, any mechanical faults or step losses that may occur are corrected directly and it can be guaranteed that the motorized stage always reaches and holds the desired position.

The precision linear stage can be easily connected to your system via the available interfaces such as Ethernet, RS485 (USB) or EtherCAT. All the necessary parameters are already preset so that closed-loop operation is possible immediately without any further programming knowledge. The simple control of the path and position of the motorized positioners can be carried out using free software, which is available for download. In addition, libraries and examples for common programs such as Matlab, LabView, C++, etc. are available.

Specifications

- Manufacturer

- GMT Global INC

- Material

- Stainless Steel

- Drive Element

- 2 Phase Stepper

- max. Speed [mm/s]

- 20 mm/s

- Travel Stroke [mm]

- 75

- Pitch [mm]

- 1mm

- Table Size [mm]

- 60x60

- Load [N]

- 140N

- Guiding Mechanism

- Circular linear ball guiding

- Weight [kg]

- 1.3

- Repeatability Accuracy

- <1µm

- Positioning Precision

- < 5µm

- Missed Step

- < 1µm

- Dynamic Parallelism [µm]

- 10 µm

- Max. Pitching Torque

- 3,33 Nˑm

- Max. Yawing Torque

- 2,5 Nˑm

- Max. Rolling Torque

- 2,5 Nˑm

Motorized Stage X-Axis CXN6075-P1

Description

GMT's CXN6075-P1 Motorized Linear Stages are suitable for a variety of applications in laser microprocessing, metrology, and optical alignment and assembly systems. The monoblock design creates a decisive advantage in terms of cost optimization and thermal stability. With this concept, no separate guide elements are required, as these are incorporated into the profile and the body and guide therefore consist of one piece.

The precision motorized stages of our CXN series have a preloaded ball screw and a positioning carriage guided by a recirculating ball bearing system, which allows long and precise traverse paths. In combination with the optionally available closed-loop stepper motor, repeat accuracies of less than 1 µm and a maximum speed of up to 60 mm/s can be achieved.

The new Ethernet connector Harting ix Industrial® is used for the motorized linear stages. The robust and miniaturized Ethernet interface replaces the RJ45 connection and ensures that your plug connection is held securely.

Thanks to the design, the sliding tables can be combined to form a multiple axis system. The drilling pattern also allows the assembly of our goniometer, rotation or lifting tables.

The advantages of the GMT high precision motorized stage systems:

- Cost-optimized concept

- Repeatability < 1µm

- Ball screw for high cycles and speeds

- Made of stainless steel

- High thermal stability

- 2-phase stepper motor from Nanotec

- Optional closed-loop stepper motors, optionally with integrated or external controller

- Harting ix connector® – for a secure connection

- Optical limit switches

- Easy to use - Plug & Play

- Compatible with other manufacturers

- For use in research, laser and measurement technology, in laboratories and in the industrial sector for the automation of precise and complex processes

The combination of our compact linear stages with the Fastech Ezi-SERVO stepper motors increases repeatability and guarantees smooth and precise positioning. Due to the integrated rotary encoder, with a resolution of >16000 pulses per revolution (ppr), the system runs permanently in closed loop mode. In this way, any mechanical faults or step losses that may occur are corrected directly and it can be guaranteed that the motorized stage always reaches and holds the desired position.

The precision linear stage can be easily connected to your system via the available interfaces such as Ethernet, RS485 (USB) or EtherCAT. All the necessary parameters are already preset so that closed-loop operation is possible immediately without any further programming knowledge. The simple control of the path and position of the motorized positioners can be carried out using free software, which is available for download. In addition, libraries and examples for common programs such as Matlab, LabView, C++, etc. are available.

Specifications

- Manufacturer

- GMT Global INC

- Material

- Stainless Steel

- Drive Element

- 2 Phase Stepper

- max. Speed [mm/s]

- 20 mm/s

- Travel Stroke [mm]

- 75

- Pitch [mm]

- 1mm

- Table Size [mm]

- 60x60

- Load [N]

- 140N

- Guiding Mechanism

- Circular linear ball guiding

- Weight [kg]

- 1.3

- Repeatability Accuracy

- <1µm

- Positioning Precision

- < 5µm

- Missed Step

- < 1µm

- Dynamic Parallelism [µm]

- 10 µm

- Max. Pitching Torque

- 3,33 Nˑm

- Max. Yawing Torque

- 2,5 Nˑm

- Max. Rolling Torque

- 2,5 Nˑm

Deutsch (Deutschland)

Deutsch (Deutschland)