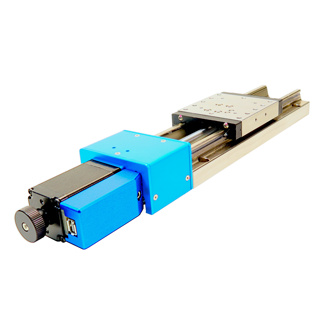

Motorized Stage X-Axis CXN60200-P2

Description

The CXN60200-P2 linear translation stage has a compact and cost-optimized design. The difference to other motorized positioning stages is that the entire body and the guide elements are made of a stainless steel profile, which means that separate guides are not required. This has the decisive advantage of higher accuracy and, above all, improved thermal stability.

The motorized positioning axes of our CXN series have a preloaded ball screw and a positioning carriage guided by a recirculating ball bearing system, which allows long and precise traverse paths. In combination with the optionally available closed-loop stepper motor, repeat accuracies of less than 1 µm and a maximum speed of up to 60 mm/s can be achieved.

The new Ethernet connector Harting ix Industrial® is used for the linear tables. The robust and miniaturized Ethernet interface replaces the RJ45 connection and ensures that your plug connection is held securely.

The advantages of the GMT high Precision motorized stage systems:

- Cost-optimized concept

- Repeatability < 1µm

- Ball screw for high cycles and speeds

- Made of stainless steel

- High thermal stability

- Can be combined XY- or XYZ stages

- 2-phase stepper motor from Nanotec

- Optional closed-loop stepper motors, optionally with integrated or external controller

- Harting ix connector® – for a secure connection

- Optical limit switches

- Easy to use - Plug & Play

- Compatible with other manufacturers

- For use in research, laser and measurement technology, in laboratories and in the industrial sector for the automation of precise and complex processes

Combining our precision translation stages with Fastech closed-loop stepper motors increases repeatability and guarantees more accurate positioning. The system continuously checks the target/actual position and compensates for any mechanical faults or step losses that may occur. This ensures that the motorized linear stage always reaches and holds the desired position.

The motorized stage can be easily connected to your system via the available interfaces such as Ethernet, RS485 (USB) or EtherCAT. All the necessary parameters are already preset so that closed-loop operation is possible immediately without any further programming knowledge. Simplifying motion control - with free software the compact linear stages can be controlled easily, or you can create your own programs using standard programs such as Matlab, LabView, C++, etc., for which libraries and examples are available.

Specifications

- Manufacturer

- GMT Global INC

- Material

- Stainless Steel

- Drive Element

- 2 Phase Stepper

- max. Speed [mm/s]

- 20 mm/s

- Travel Stroke [mm]

- 200

- Pitch [mm]

- 2mm

- Table Size [mm]

- 60x60

- Load [N]

- 140N

- Guiding Mechanism

- Circular linear ball guiding

- Weight [kg]

- 2

- Repeatability Accuracy

- <1µm

- Positioning Precision

- < 5µm

- Missed Step

- < 1µm

- Dynamic Parallelism [µm]

- 15 µm

Motorized Stage X-Axis CXN60200-P2

Description

The CXN60200-P2 linear translation stage has a compact and cost-optimized design. The difference to other motorized positioning stages is that the entire body and the guide elements are made of a stainless steel profile, which means that separate guides are not required. This has the decisive advantage of higher accuracy and, above all, improved thermal stability.

The motorized positioning axes of our CXN series have a preloaded ball screw and a positioning carriage guided by a recirculating ball bearing system, which allows long and precise traverse paths. In combination with the optionally available closed-loop stepper motor, repeat accuracies of less than 1 µm and a maximum speed of up to 60 mm/s can be achieved.

The new Ethernet connector Harting ix Industrial® is used for the linear tables. The robust and miniaturized Ethernet interface replaces the RJ45 connection and ensures that your plug connection is held securely.

The advantages of the GMT high Precision motorized stage systems:

- Cost-optimized concept

- Repeatability < 1µm

- Ball screw for high cycles and speeds

- Made of stainless steel

- High thermal stability

- Can be combined XY- or XYZ stages

- 2-phase stepper motor from Nanotec

- Optional closed-loop stepper motors, optionally with integrated or external controller

- Harting ix connector® – for a secure connection

- Optical limit switches

- Easy to use - Plug & Play

- Compatible with other manufacturers

- For use in research, laser and measurement technology, in laboratories and in the industrial sector for the automation of precise and complex processes

Combining our precision translation stages with Fastech closed-loop stepper motors increases repeatability and guarantees more accurate positioning. The system continuously checks the target/actual position and compensates for any mechanical faults or step losses that may occur. This ensures that the motorized linear stage always reaches and holds the desired position.

The motorized stage can be easily connected to your system via the available interfaces such as Ethernet, RS485 (USB) or EtherCAT. All the necessary parameters are already preset so that closed-loop operation is possible immediately without any further programming knowledge. Simplifying motion control - with free software the compact linear stages can be controlled easily, or you can create your own programs using standard programs such as Matlab, LabView, C++, etc., for which libraries and examples are available.

Specifications

- Manufacturer

- GMT Global INC

- Material

- Stainless Steel

- Drive Element

- 2 Phase Stepper

- max. Speed [mm/s]

- 20 mm/s

- Travel Stroke [mm]

- 200

- Pitch [mm]

- 2mm

- Table Size [mm]

- 60x60

- Load [N]

- 140N

- Guiding Mechanism

- Circular linear ball guiding

- Weight [kg]

- 2

- Repeatability Accuracy

- <1µm

- Positioning Precision

- < 5µm

- Missed Step

- < 1µm

- Dynamic Parallelism [µm]

- 15 µm

Deutsch (Deutschland)

Deutsch (Deutschland)